Success Case

Client: Scania

How ZYGHT supported Scania in becoming leaders in sustainable transportation

For Scania - as one of the companies with the most sustainability initiatives and with the goal of being a benchmark in HSE in its field, the main challenge is the digitalization of their processes towards sustainable and environmentally friendly behavior.

Industry: Manufacturing of Transportation Vehicles

Headquarters: Södertälje, Sweden Organization

Size: More than 50,000 employees in 100 countries

About Scania

Based in Södertälje, Sweden, Scania is a global leader in transportation solutions, including trucks and buses for heavy transport applications, combined with a range of product-related services. Its commitment to sustainability and its pursuit of being a benchmark in health, safety, and environment in its industry make it a key player in the transformation towards more responsible practices.

The Challenge:

Manual Processes for Tracking and Managing HSE Data

Before implementing ZYGHT, Scania faced various challenges. The company had a basic software for incident recording, but it lacked notifications, dashboards, and effective integration with the rest of the organization. This software was limited as it did not allow for proper tracking and closure, making incident management and accurate data collection difficult. Scania recognized the need for a more comprehensive system that answered the key questions of their action plan: what, how, when, and who. Scania was looking for a system that would provide clear and specific measures, both short and long term, identifying those responsible for each action and allowing for effective follow-up.

Before ZYGHT's implementation, the department responsible for health, safety, and environment at Scania worked with documents and statistical charts manually. Digitalizing these processes was essential to streamline the work and ensure more accurate record-keeping.

The Solution

Scania's action plan was aligned with what they expected from an HSE management system like ZYGHT. The "What" focused on prevention and control measures, based on elimination, substitution, engineering control, warning signage, and administrative control, ending with personal protective equipment (PPE). The "How" was centered on the timeline, defining as immediate action anything resolved within 3 days, short-term projects resolved in 7 days, and long-term projects that could take up to 14 days. The "When" was related to the completion date, and the "Who" corresponded to the person in charge.

Regarding the implementation of ZYGHT's SaaS solution at Scania, it was a well-planned project that involved over 100 people. Promoting the internal use of ZYGHT was one of the objectives of Scania's HSE team. Currently, they are training 40 new team leaders in risk management and usage, as well as providing brief trainings to leaders in incident management.

The Result

Improved communication and visibility of deviation reports: Previously, reports were confined to one area and not widely shared across the organization. However, with ZYGHT, it is now possible to access the information more easily and see everything that is happening, including who has reported, where it has been reported, and what type of deviation it is, as well as accidents, incidents, and rounds conducted. This has generated greater trust, as users are aware of everything that is happening.

During the year 2022, the company achieved a closure rate of nearly 90% for on-site deviations. Between 2022 and the first half of 2023, more than 1,000 deviations were opened, and they are preparing for the year-end audit, promoting participation and collaboration in risk management. The projection is that these numbers will continue to grow and increasingly impact the optimization of times related to administrative tasks.

Follow-up and Closure of Reports:

For Scania, it is very important that the system allows for additional comments in all cases, facilitating the process of palliative closure and continuous improvements in the deviation flow in which they are working together for short-term implementation.

Greater Sustainability of the Organization through Digitalization:

The digitalization of most paper documents has helped reduce their use and comply with standards and regulations, especially in the context of the pandemic. Previously, accident reports were printed and stored in physical folders, but now that process has been eliminated, and the reports are stored in the cloud, allowing for faster and more efficient access to information.

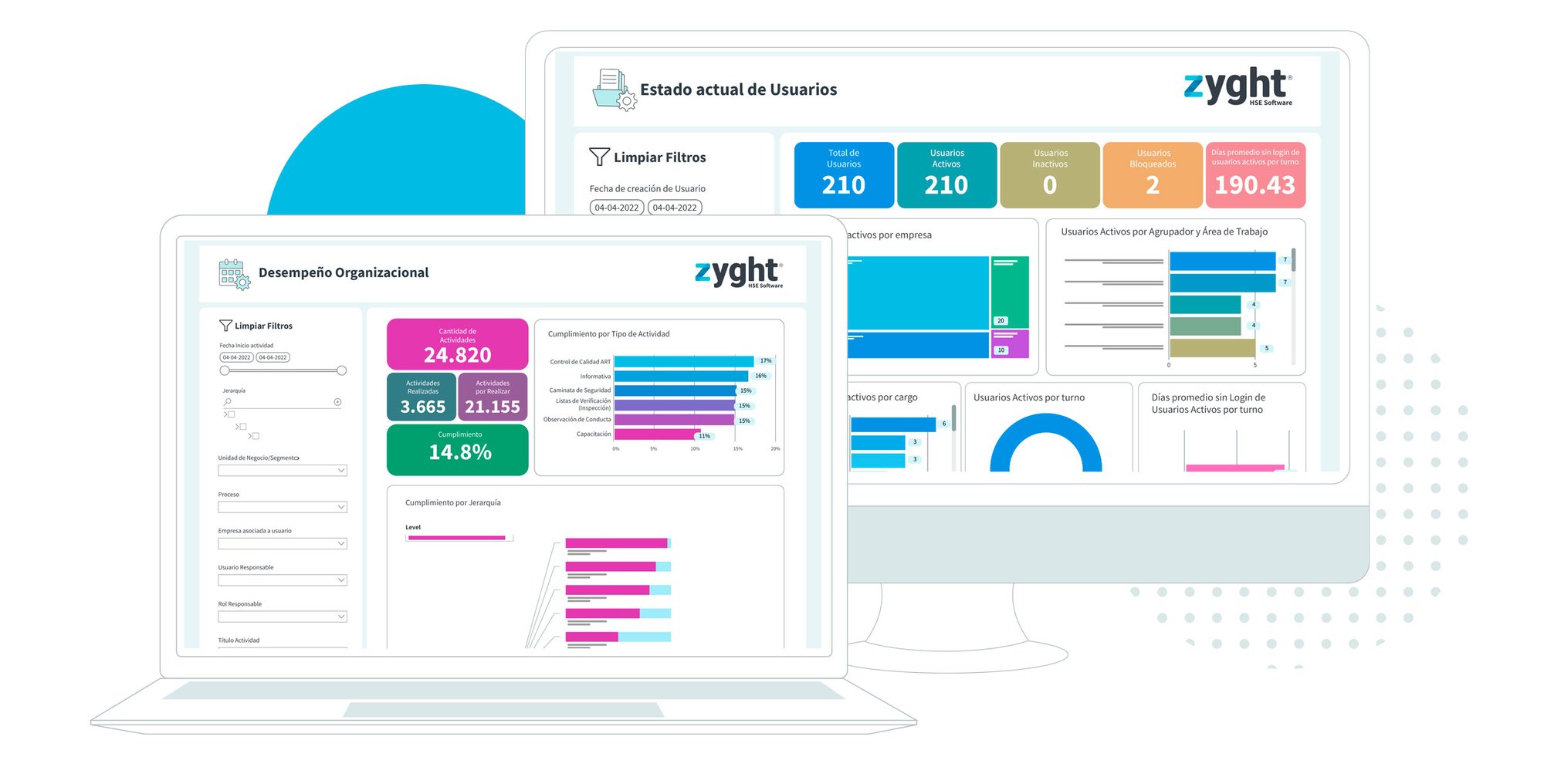

"Another aspect to highlight is the access to information that ZYGHT facilitates for any collaborator of the organization, which is projected through the control panels, displayed on screens at strategic points of the company. This allows for an overall view of the situation and facilitates informed decision-making. Having real-time information is very valuable to stay up to date with relevant data and to be able to act quickly based on it. These controls and dashboards are useful tools for monitoring progress, identifying deviations, and making adjustments as necessary." - Jimena Toledo, HSE Specialist at Scania Argentina.

Projection with ZYGHT

Adding Work at Height Permit and Non-Routine Work Permit in the future. One of the features most used is the Analysis Control, which is especially used as a round during maintenance seasons with contractors and own staff, resulting in a very important preventive control in the company during factory closures.

Scania has worked together with an ISO 45001 standard advisor to review the platform from end to end to ensure they are prepared for a legal audit, as demonstrated during the visit to Scania Latin America, held in Brazil. This has allowed them to identify areas for improvement and ensure they have adequate responses in case of accident-related inquiries.

During the year 2022, the company managed to close to 90% of deviations in the field. Between 2022 and the first half of 2023, more than 1,000 deviations were opened, and they are preparing for the year-end audit, promoting involvement and collaboration in risk management. The projection is that these numbers will continue to grow and increasingly impact the optimization of times related to administrative tasks.

Summary

Challenge: Digitalize manual processes for tracking and managing HSE data.

Results: Improved communication and visibility of deviation reports, follow-up and closure of reports, and increased organizational sustainability through digitalization.

Impact: During the year 2022, the company achieved a closure rate of nearly 90% for on-site deviations. Between 2022 and the first half of 2023, more than 1,000 deviations were opened.